Keeping energy costs in check

Digital energy management

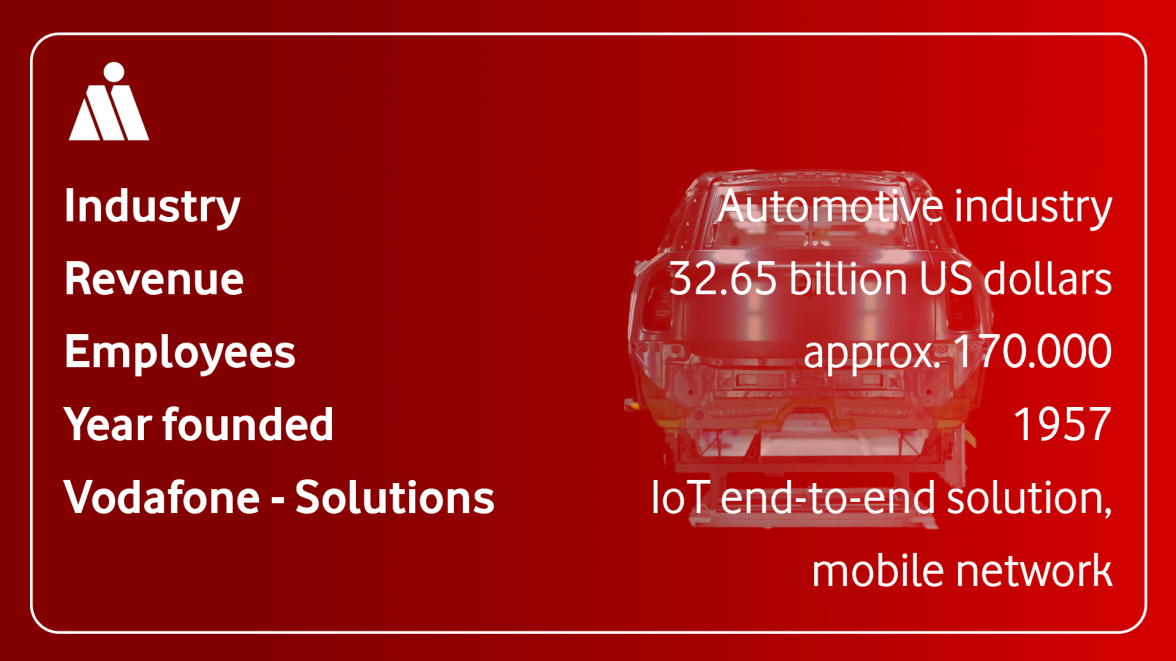

The example of Magna

The example of Magna

Digital energy management in the industrial sector

Energy is a valuable commodity. This has always been the case, but the crises of recent years have greatly increased the need to use electricity and heat in a targeted manner. The case of automotive supplier Magna shows how digital solutions in the field of energy management can offer a way out of the emergency - and also ensure greater sustainability.

Potential savings through digital energy management, based on annual consumption.

The Challenge

Energy is an expensive commodity

The rising energy prices of recent months pose considerable challenges for the German economy. In a recent survey by the Chamber of Industry and Commerce, 15.6 per cent of industrial companies stated that they had already considered reducing production or discontinuing certain business areas due to the current energy price situation. In energy-intensive sectors, this figure is even twice as high at 31.9 per cent. (Source: Energy transition barometer 2022 of the IHK organisation)

The good news: there are solutions. Digital technologies help companies to make their energy consumption more transparent and identify potential savings in the long term. This not only helps to reduce costs, but also protects the climate: the potential savings in CO2 emissions in the industrial sector that could be achieved by 2030 through digitalisation are estimated at 37 to 64 million tonnes. (Source: Study "Climate effects of digitalisation", Bitkom 2021)

Rising costs

The Company

A global leader

The production and development of vehicle parts consume a lot of energy - but how and where exactly? This is precisely what automotive supplier Magna wanted to find out with the help of the IoT network from Vodafone Business in order to make energy management more transparent and effective. With over 158,000 employees at more than 400 locations in 27 countries, Magna is one of the world's leading automotive suppliers. From individual components to the production of entire vehicles, Magna offers its customers worldwide a wide range of solutions.

In order to sustainably improve its own energy consumption and thus reduce costs in the long term, the Canadian company sought a solution for all-encompassing, transparent energy management.

The Solution

Transparency thanks to digitalisation

Magna decided to work closely with Vodafone to record consumption data and network its individual branches. The reading and transmission of meter readings is realised on the basis of the IoT network. Thanks to a highly flexible and modular solution, existing systems are integrated regardless of manufacturer and meters already installed are connected via existing interfaces - for example M-Bus, Zigbee, Modbus, C-Bus LOM, BACNET, or others. If required, Vodafone also provides sub-meters in various technical versions. Data loggers aggregate the meter readings and transmit them via a gateway equipped with an IoT SIM card to the energy management portal and the data analysis platform based on it.

More efficiency through transparency

The Advantages

At a glance

Magna can realise enormous savings through consistent energy management monitoring. The topic has become a must for every company, not least due to exploding energy costs. Digital energy monitoring not only increases efficiency and productivity, but also scores highly in terms of sustainability, as it contributes to a significant reduction in energy consumption.

Transparent overview

of the consumption of all connected systems

Extensive analyses

consumption and cost breakdowns as well as optimisations thanks to the dashboard

Safe and reliable

End-to-end solution based on the Vodafone IoT network

Low investment costs

hardly any IT effort and full scalability

5 questions for Stefan M. Büttner

5 questions for Stefan M. Büttner

5 questions for Stefan M. Büttner, energy expert and institute director

Savings through digitalisation

Energy efficiency measures are often not a question of budget, but of knowledge, as for many companies it means having to venture into unfamiliar areas, says Stefan M. Büttner. Here he reveals the benefits that successful energy management can bring companies.

Energy management should be as flexible as possible.

Stefan M. Büttner – Head of Global Strategy & Impact,

Institute for Energy Efficiency in Production (EEP)

Stefan M. Büttner, Head of Global Strategy & Impact at the Institute for Energy Efficiency in Production (EEP) and author, speaker and chair of various UN working groups, focuses on working with companies, politicians and society to make a climate-neutral economy possible.

For which companies is digital energy management worthwhile?

Stefan M. Büttner: In principle, it is worthwhile for every company, as it makes it easier to identify anomalies in consumption and uncover efficiency potential. In addition, digital energy management makes it possible to adapt processes in line with demand, operate active load management and integrate renewable energies and storage in a meaningful way. It also facilitates the preparation of sustainability reports, as companies can use it to calculate the appropriate constellation from a large number of possible efficiency measures. This cannot replace an audit, but it can increase its usefulness, as potentials are identified more easily and the risk of overlooking something worthwhile is reduced.

In a study for the Federal Ministry for Economic Affairs and Climate Protection (BMWK) in 2017, we identified the technical savings potential of the top ten innovations available on the market: It accounts for around a third of total consumption in the industrial sector. Advances in many technologies and digital solutions in recent years are likely to have further increased the savings potential.

What should companies look out for when deciding to digitalise their energy management?

Stefan M. Büttner: Energy management should be as flexible as possible and not be dependent on the configuration of production. This means that it can also function if other machines are used or the mode of utilisation changes. It is equally important to think about security from the outset in order to be armed against hacker attacks, for example. Sharing information with other energy managers can be very helpful here. Ultimately, however, the human component is crucial, i.e. getting employees on board and involved.

Digital energy management enables processes to be adapted in line with demand, active load management to be carried out and renewable energies and storage to be integrated in a meaningful way.

Stefan M. Büttner, Head of Global Strategy & Impact, Institute for Energy Efficiency in Production (EEP)

Why is reliable and transparent data so important for efficient energy management?

Stefan M. Büttner: It's like travelling on a road trip. I can only find an effective route to my destination if I know where I am. Without reference points or due to incorrect assumptions, you can very quickly find yourself on the wrong route. It's basically the same with energy management.

What is the biggest obstacle to implementing energy efficiency measures in companies?

Stefan M. Büttner: Generally speaking, energy efficiency is complex. It's difficult to know your way around all the different facets. This currently applies above all to the area of waste heat utilisation, where there is a lack of experts who could help to identify and exploit potential, also in order to counter the gas crisis. The limited availability of materials and installers makes it even more difficult to implement measures.

If my share of energy costs in the company has been comparatively small up to now, I may not have anyone who knows the ropes. In this respect, it often seems easier to increase turnover in order to compensate for additional energy costs than to intervene in functioning processes. This is why it often remains with the so-called auxiliary processes such as lighting or heat supply. But the current crisis may change this.

Energy efficiency and sustainability go hand in hand.

If you were the energy officer of a medium-sized company, what would be your top five energy-saving measures?

Stefan M. Büttner: The industrial sector is very diverse, so the top five measures depend heavily on what my company produces, which energy sources I use and how energy-intensive my business is. In this respect, my top five are the following general steps:

- Systematically record energy consumption according to generally applicable standards for all energy sources.

- Involve the workforce in recognising and eliminating unnecessary energy and resource consumption, but also ask for ideas to increase efficiency - with a reward system if necessary.

- Introduce a structured energy management approach, including the recording of efficiency potential, digital monitoring of consumption and an implementation roadmap.

- Agree a dedicated energy efficiency budget with the management or automatically include measures up to a certain threshold (cost per kWh saved) in the investment budget and then, of course, implement them.

- If possible, bundle responsibilities for sustainability, decarbonisation, energy management and energy procurement, because emissions and energy procurement costs have a direct impact on the profitability of efficiency measures and the resilience of the company.

Thank you very much for this interview, Mr Büttner!

5 tips | Reduce energy costs

5 tips

5 tips

How to reduce energy costs in your company

Improving energy efficiency is currently a top priority for companies. Climate change and the energy transition had already put the topic on the agenda of many companies; the Ukraine war and the associated rise in energy costs have made the issue even more important. The fact is that companies can reduce their electricity costs by five-figure sums every month by improving their energy efficiency - even with just a few simple measures.

Want to find out more? We present 5 measures to reduce energy costs that companies can implement in the short or medium term:

Optimising lighting

Most companies should be aware by now that significant savings can be made by adapting electrical lighting - the German Energy Agency (dena) speaks of a reduction in energy costs of up to 70 per cent. Nevertheless, there is often still room for improvement: Modern LED lamps enable significant savings, even compared to conventional energy-saving lamps, and have an impressive service life.

Most LED lamps can burn for up to 20,000 hours, which is a full two years of light without interruption and twice as many hours as an energy-saving lamp. Intelligent sensors that automatically switch off lights when no one is in the room can also significantly improve the energy balance.

Avoid standby mode

One energy guzzler that is still underestimated is standby mode, which is used on the vast majority of electronic devices. Simply avoiding standby mode can reduce the power consumption of many devices by ten per cent. Larger devices such as printers or external screens should therefore always be switched off completely when nobody is using them.

Small electrical accessories should also not be forgotten - chargers and adapters constantly consume electricity as long as they are connected to the mains. Power strips with an on-off function can be a sensible purchase to get these hidden costs under control. In offices in particular, care should be taken to ensure that electricity does not flow unnecessarily over the weekend.

Precise measurements can be used to identify power guzzlers and reduce energy consumption.

Finding power guzzlers

In the manufacturing industry in particular, a large proportion of electricity consumption is caused by the operation of machines. Companies should therefore keep an eye on older devices in particular and identify power guzzlers. An abnormal increase in energy consumption can often also signal a defect - if such an increase is recognised quickly, the company can ideally even take countermeasures in good time and avoid a machine failure. This not only reduces energy costs, but also improves the efficiency of the machines while simultaneously reducing their maintenance costs.

Measure consumption accurately

Accurate measurement of electricity consumption is crucial in order to improve energy efficiency in the company and reduce energy costs. This is the only way to record consumption peaks in terms of time and space and identify potential savings. While it may be sufficient for some companies to carry out regular measurements, for others the question will arise as to whether permanent consumption monitoring is the better option. The option of remote reading can also be relevant for some companies.

Ideally, such measurement can fulfil all the requirements of Section 8a of the Energy Services and Other Energy Efficiency Measures Act (EDL-G), in particular those of DIN EN 16247, as energy audits have been mandatory for larger companies since 2015.

Simple measures, big impact: significant energy savings are possible even with small interventions.

Optimising heat distribution

Another area in which companies can make significant savings is the heating of buildings. There are various options here: For example, heat distribution can be optimised by hydraulic balancing. This measure, which can be implemented quickly and for little money, is set to become mandatory for larger buildings anyway - as stipulated in the government's second Energy Saving Ordinance, which came into force in October.

Another option is to install a high-efficiency pump in accordance with EU eco-design guidelines. Such heating pumps are much more economical in terms of consumption than older models, which can often become real power guzzlers.

In order to implement the steps mentioned above in a targeted and effective manner, it can make sense to consider digitalising the company's internal energy management. Companies can utilise various options for this.

For example, the energy data management solution (EDM) from Vodafone Business, which allows companies to precisely track their energy consumption. A scalable system consisting of suitable measurement technologies and data loggers is installed at the various locations.

The simple plug-and-play solution Modbus Cloud Connect from Vodafone and grandcentrix also creates transparency. The product forms the digital bridge between Modbus RTU devices and the company's cloud infrastructure. Machines and systems are thus given an IoT upgrade thanks to simple retrofitting.

Want to find out which solution is right for your company? We will be happy to advise you!